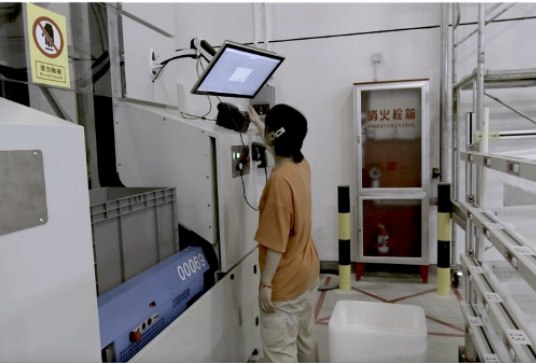

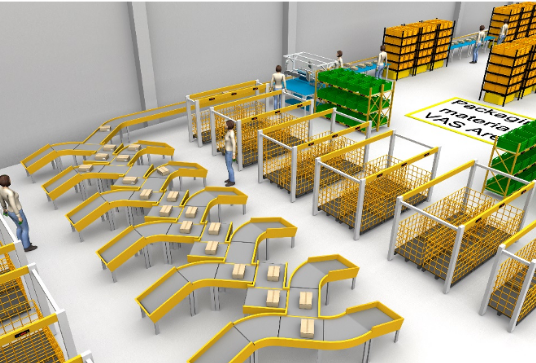

Automation

Providing an all-round automated warehouse solution to solve human resource challenges

Solutions

Different equipment, such as automated shelves and sorting systems, are integrated and inter-connected. Flexibility, A.I. and data are the crux of our solutions and every operation is data-driven.

AGV Picking

ASRS-Carton

ASRS-Pallet

Shuttle Sorting

Reference

Food & Beverage Industry

- Operation model: Fulfillment,E-Commerce

Original sorting & picking:

- Manpower: 7 × sorting, 5 × picking

- Throughput: 2,000 pcs/hour

New sorting:

- Manpower: 3 × sorting, 3 × picking

- Throughput: 5,400 pcs/hour

Food & Beverage Industry + Express Industry

- Operation model: Fulfillment, E-Commerce

Original warehouse (Express):

- Site Area: 2 × 50,000 sq ft

- Manpower: 27 × sorting, 2 × forklift

- Throughput: 4,000 parcels/hour

Original warehouse (F&B):

- Site Area: 1 × 50,000 sq ft

- Manpower: 24 × sorting, 5 × forklift, 10 × picking

- Throughput: 3,500 pcs/hour

New warehouse:

- Site Area: 70,000 sq ft

- Manpower: 5 × sorting, 2 × forklift, 6 × picking

- Throughput: 20,000 pcs/hour

Fashion Industry

- MHE (Racking, Conveyor system, Rapid Shutter..)